Medium Dark Roast

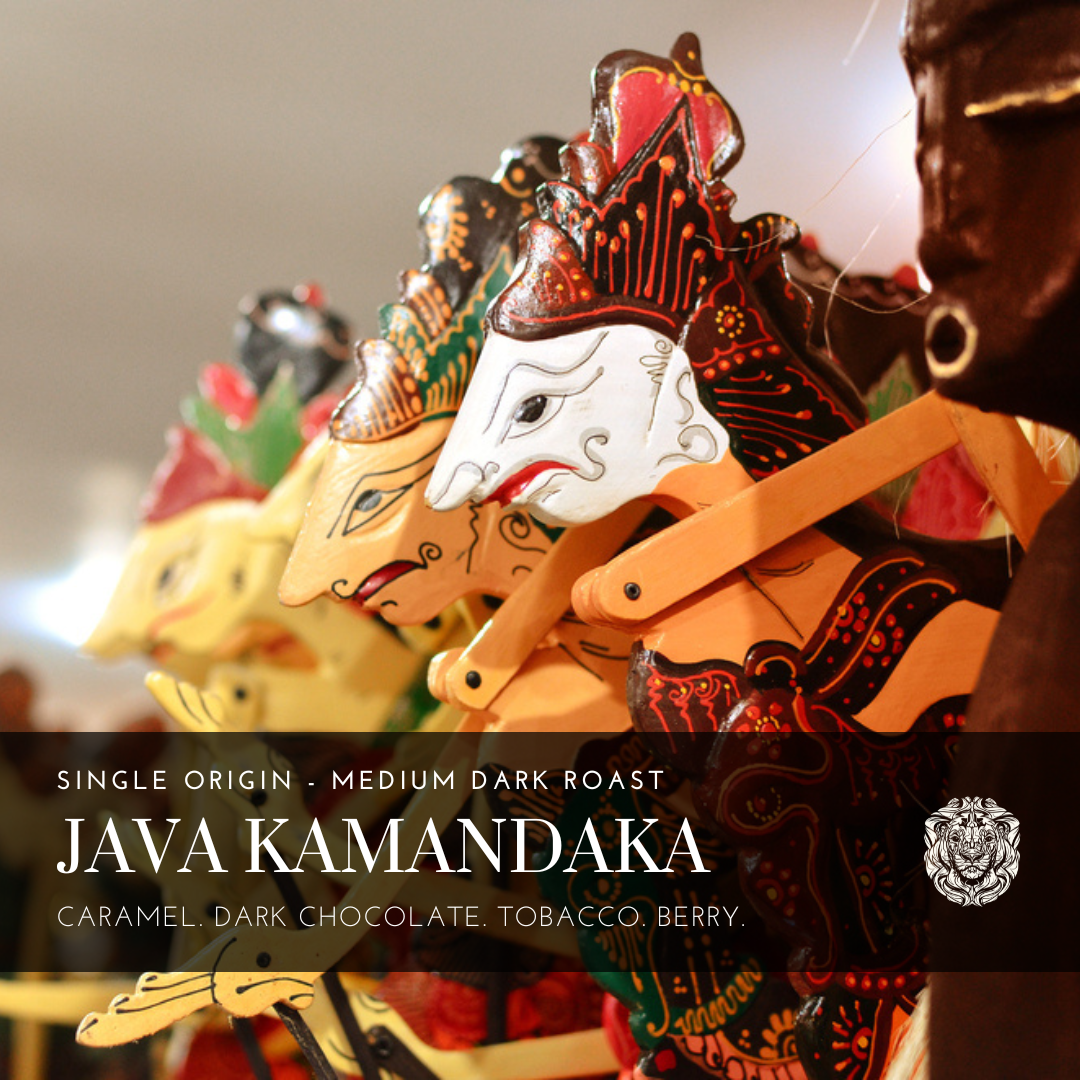

Java Kamandaka

Java Kamandaka

Medium Dark

What is Wet-Hulled?

Indonesia is known for its unique wet-hulled process (giling basah). After handpicking cherry, farmers process their cherry using the traditional wet hulling (giling basah) method. Following harvest, cherry is pulped at or near the farm, on small hand-cranked or motorized pulpers. The coffee is fermented for approximately 12 hours (in small tanks, buckets or bags) and washed with clean water the following morning. Parchment is sun-dried for between half a day and two days, depending on the weather, to allow for skin drying which eases the removal of parchment.

At this juncture the moisture content is between 30-40%. Farmers deliver their parchment to a collector. Collectors may either wet hull the parchment themselves or sell the parchment on to someone who will. These steps become an essential part of the process here because a wet hulling machine, though slightly different, requires a similar investment to a dry huller. Wet hullers are larger, require more power and run at a faster speed than a traditional dry huller. Few, if any, individual farmers have their own hullers.

After hulling, the coffee seed is whitish and pliable and is called labu. It is laid out to dry on tarps or patios, where it reduces in size and moisture decreases to 14-15%. This stage the green coffee is known as asalan—unsorted and with defects. Much of the internal commercial trade is for asalan. Exporters, most of whom are based in Medan, will typically finish the drying down to 12-13%, sort and prepare for shipment.

Couldn't load pickup availability